|

516-223-2300 | Info@TechPacInc.com |

|

Serving the Long Island New York Area |

||

|

STYLES |

|

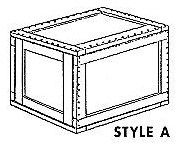

CLEATED PLYWOOD BOXES UP TO 2500 lbsSimilar to PPP-B-601 but with a stronger base and support for the top:

|

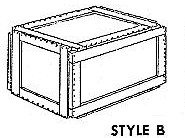

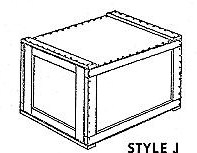

CLEATED PLYWOOD BOXES UP TO 30,000 lbsTwo types and two styles of sheathed crates as follows: |

|

|

NAILED WOOD LUMBER BOXES

|

TYPE

|

GRADES

|

|

|

|

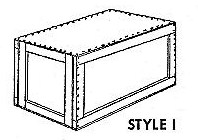

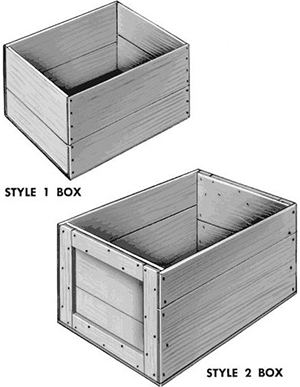

Style 1 Nailed Wood Box - identified by lack of cleats on the ends and single line nailing of sides to ends, and of top and bottom to ends and sides. Style 1 box is intended for domestic shipments only and may not exceed a load limit of 50 pounds for two-piece sides and 100 pounds for one-piece sides. This box is limited to a height of 10 inches and total dimensions (length, width, and depth) of 50 inches.

Style 2 Nailed Wood Box - identified by two vertical and two horizontal cleats on each end. Vertical cleats are positioned at right angles to the grain of the end. They are one-eighth of an inch shorter than the edge of the end at the top and bottom. Horizontal cleats, which are placed parallel to the grain of end, are butt-joined to the vertical cleats and are flush with the top and bottom edges of the box. The top, bottom, and sides extend over the ends and cleats and are nailed in a staggered pattern. Thus, there is some side-grain nailing on all edges. The cleat pattern provides ease of handling. Weight limitation for Style 2, Class 1 box (domestic) is 600 pounds. Weight limitation for Style 2, Class 2 (oversea) box is 1,000 pounds.

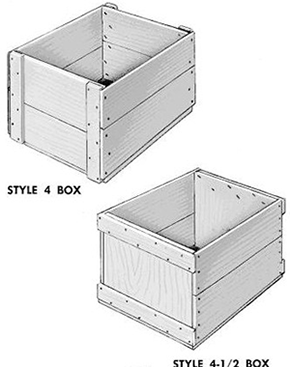

Style 4 Nailed Wood Box - Style 4 box is identified by two vertical cleats on each end. Vertical cleats, which are positioned at right angles to the grain of the end, are one-eighth inch shorter than the outside surfaces of the top and bottom of the box. The top and bottom cover the sides. They fit between the cleats and are attached to the ends by straight line, side-grain nailing. The sides overlap the ends and cleats, providing for a staggered nailing pattern. Weight limitation for Style 4, Class 1 box (domestic) is 250 pounds. Weight limitation for Style 4, Class 2 box (oversea) is 400 pounds.

Style 4-1/2 Nailed Wood Box - identified by two horizontal end cleats. Horizontal cleats, which are positioned at right angles to the grain of the end, are one-eighth inch shorter than the outside surface of the sides. The sides extend over the ends, and provide for straight-line, side-grain nailing. The top and bottom extend over the ends and cleats, an provide for both side- and end-grain nailing. Weight limitations for both classes of boxes are the same as for Style 4 boxes.

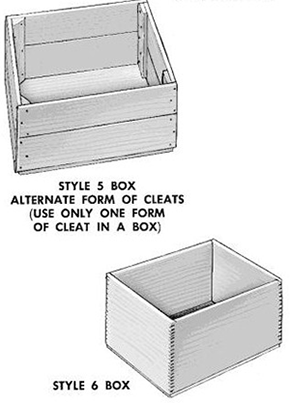

Style 5 Nailed Wood Box - identified by interior vertical cleats. The cleats extend to within one-eight inch from the top and bottom edges of the end of the box. Other than the placement of cleats, construction and nailing pattern for this container is the same as for Style 4 box. The interior cleats may be rectangular or triangular, provided the cross section area of the triangular cleat is not less than that of the required rectangular cleat. Weight limitation for Style 5, Class 1 box (domestic) is 250 pounds. Weight limitation for Style 5, Class 2 box (oversea) is 400 pounds.

Style 6 Nailed Wood Box - Style 6 box is identified by the lock corner construction which is glued. This box has about the same advantages and disadvantages as Style 1 box. Style 6 box is intended for domestic shipments only and has a weight limitation of 50 pounds, but may go to 100 pounds if the box has one-piece sides.

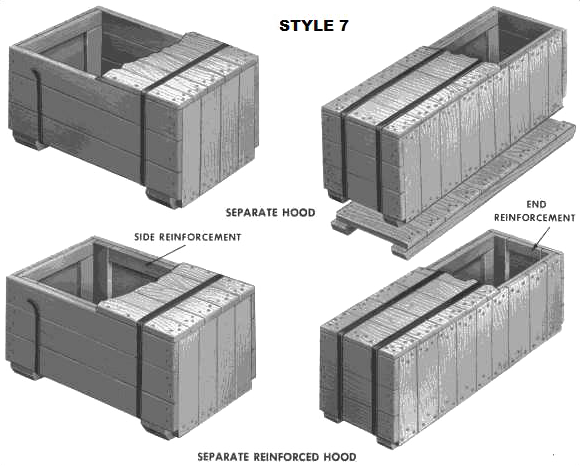

Style 7 Nailed Wood Box - an internally reinforced box consisting of a skidded base with a separate hood assembled from the top, sides and ends. Style 7 boxes are for contents ranging from 100 to 1,000 pounds. The contents must readily permit attachment to the skids. The base is assembled to 2 X 4 inch skids to facilitate mounting to a skid base. The skids are positioned across the extreme ends of the bottom pieces to permit attachment of all end pieces to the skid edges. Vertical and horizontal framing members and reinforcing members in the form of a rectangle, and cross diagonals, as applicable, are attached to the interior surfaces of the prefabricated box panels. Framing members are required when contents exceeds 250 pounds or when side length is greater than end length. End panels are identified by vertical sheathing which extends within one-eighth of an inch of each skid bottom. The hood assembly is placed over the item mounted to the base, then nailed and strapped. Style 7 boxes are intended for both Class 1 and Class 2 use.

Bracing Detail

Bracing Detail

Bracing Detail

Bracing Detail

Custom Skid

Custom Skid

Custom Skid Front

Custom Skid Front

Custom Skid Rear

Custom Skid Rear

Custom Skid Side

Custom Skid Side

Custom Skid Side

Custom Skid Side

Custom Skid Side

Custom Skid Side

Custom Skid with Metal Braces

Custom Skid with Metal Braces

Finished Crates

Finished Crates

Hardwood Bracing

Hardwood Bracing

Painted Mil Spec Crate

Painted Mil Spec Crate

Pallets

Pallets

Pallets with Donuts

Pallets with Donuts

Saddle Bracing Detail

Saddle Bracing Detail

Saddle with Triwall & Foam

Saddle with Triwall & Foam

Wood Box with Saddles

Wood Box with Saddles

Wood Boxes

Wood Boxes

Wood Saddles

Wood Saddles

Covered Wood Crate

Covered Wood Crate

Foam Lined Lumber Crate

Foam Lined Lumber Crate

Stock & Release Lumber Crates

Stock & Release Lumber Crates

DW Folder with Wood Ends

Dhtml Slideshow by VisualLightBox.com v5.3

DW Folder with Wood Ends

Dhtml Slideshow by VisualLightBox.com v5.3