|

Box Styles |

| All boxes made IAW ASTM D5118 and D5168. |

| |

|

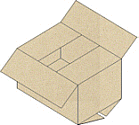

Regular Slotted Container (RSC) - All of the flaps of an RSC are the same length and the lengthwise or outer flaps meet in the middle. These are the most economical boxes to manufacture and use. Additional protection can be given with top and bottom pads. |

|

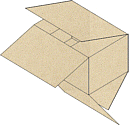

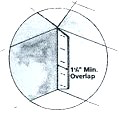

Full Overlap Slotted Container (FOL) - All of the flaps of an FOL are the same length with the outer flaps almost completely overlapping. When an FOL is stacked on one of its side panels, the extra thicknesses of corrugated on the top and bottom provide added stacking strength. When stacked on its bottom panel, the extra flaps provide additional cushioning. |

| |

|

|

|

|

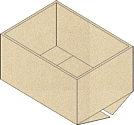

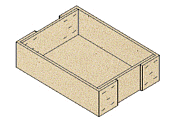

Half Slotted Carton (HSC) - A variation of the RSC with flaps on only one end. Commonly used with a top cover or slotted tray where the application requires frequent removal and replacement of the cover. Also used with the flaps on top fitted over large or heavy items attached to a pallet or wood base. |

|

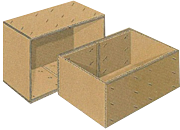

Sleeve or Double Cover (DC) Box - Basically an RSC with no flaps. The DC box is popular for tall or heavy items that would be difficult to pack in a standard carton. It can easily be cut down for use with items of varying height. |

| |

|

|

|

|

Slotted Tray - used in conjunction with an HSC or sleeve. Also frequently employed for in-house material transport and storage. Usually shipped flat and set up by the user by stapling or gluing. |

|

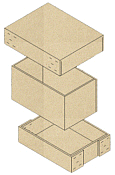

Full Telescoping Carton (FTC) - A two piece box with a full depth cover. The extra layers of corrugated on the sides gives additional stacking strength and protection. Well suited for items where a flat bottom is desirable, e.g. paper, brochures, books, etc. Usually shipped flat and set up by the user by stapling or gluing. |

| |

|

|

|

|

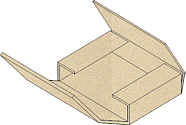

One Piece Folder (OPF) - Flat bottom with outer flaps that meet or overlap with inner "tuck" flaps of a specified length (usually two to three inches). OPF's are frequently manufactured with multiple height scores enabling one size to be used for different items or multiples of the same item. One-Piece Folders are used to package shallow depth items such as books and pictures. |

|

Five Panel Folder (5PF) - A 5PF when assembled has multiple layers of corrugated at each end. This provides considerable strength and is excellent for packing long heavy items (rods, light fixtures, linear bearings, etc.) of small diameter which might easily break through the ends of a standard container. |

| |

|

|

|

|

Double Slide Box (DS) - Inner slide may be either open or glued. Outer sleeve can be glued or stitched. Double cushion on sides and corners make this box good for pharmaceutical packaging, books, etc. A variation of the DS is the government Fast Pack or Slide Pack which is lined with convoluted foam. |

|

Partition and Dividers - These provide a separate cell for the protection of glass, earthenware, pottery and other fragile items. For additional protection they can be constructed with an air space between the items and the exterior walls of the box. |

|

BOX STRUCTURE |

|

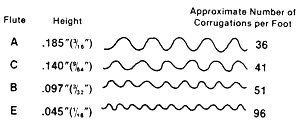

Common Flute Sizes

|

|

Corrugated board is made largely of recycled paper and most commonly comprises three components: an outer and inner "liner" and a "corrugating medium" or "fluting," which is glued between the liners. It is this sandwich-type construction that gives corrugated board its excellent rigidity and structural strength as well as its unique cushioning characteristics. The letter designations relate to the order that the flutes were invented, not their relative sizes. Measuring the number of corrugations per foot is the best way of identifying flute size because board thickness can vary slightly for different manufacturers and conditions. For box stacking strength, A flute is a good choice. For greater crush resistance, B Flute, with more lines of contact between the flutes and the facings is a better choice. A good compromise is C flute which also is the most common.

|

|

|

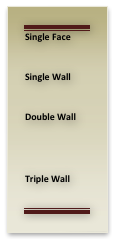

Board Construction Single Face corrugated is a sheet of fluted medium glued to linerboard on one side only. In this way, the corrugations are held firm and prevented from stretching or flattening. Single face can be purchased in 24" or 36" rolls and is used principally for wrapping and interior packaging.

Box strength is measured in two different ways. The Mullen Test measures resistance to rupture in pounds per square inch (psi). Below are guidelines used by the transportation industry for the last century:

|

|

|

|

| SINGLE WALL CONTAINER

|

| MULLIN MIN BURSTING STRENGTH (LBS/MSF) |

CARTON PERIMETER (INCHES) |

MAX WEIGHT OF BOX AND CONTENTS (POUNDS) |

| 150 Test |

50 |

35 |

| 200 Test |

75 |

65 |

| 275 Test |

95 |

95 |

| 350 Test (V3c) |

105 |

120 |

| |

|

|

|

Edge Crush Test (ECT) measures the stacking

strength of corrugated cardboard boxes. Compression strength is

defined by the amount of force in pounds per square inch that is

needed to crush corrugated by standing it on its edge. For example,

a box with an ECT rating of 32 lbs per inch indicates that the

cardboard used in the box, standing on edge, can withstand a force

of 32 lbs. per inch before crushing. The tables below compare Mullin

and Edge Crush. |

|

|

|

|

|

SINGLE WALL CONTAINER

|

Mullin Minimum Bursting Strength

(LBS/MSF) |

Stacking Strength

(Pounds/Inch) |

Maximum Weight of Box and Contents (Pounds) |

| 150 Test |

ECT 26 |

35 |

| 200 Test |

ECT 32 |

65 |

| 275 Test |

ECT 44 |

95 |

| 350 Test |

ECT 55 |

120 |

|

|

|

DOUBLE WALL CONTAINER |

Mullin Minimum Bursting Strength

(LBS/MSF) |

Stacking Strength

(Pounds/Inch) |

Maximum Weight of Box and Contents (Pounds) |

| 275 Test |

ECT 48 |

100 |

| 350 Test |

ECT 51 |

120 |

| 500 Test |

ECT 65 |

160 |

|

|

|

TRIPLE WALL CONTAINER |

Mullin Minimum Bursting Strength

(LBS/MSF) |

Stacking Strength

(Pounds/Inch) |

Maximum Weight of Box and Contents (Pounds) |

| 700 Test |

ECT 67 |

240 |

| 900 Test |

ECT 80 |

260 |

| 1100 Test |

ECT 90 |

280 |

| 1300 Test |

ECT 112 |

300 |

|

|

|

| |

|

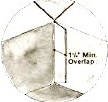

MANUFACTURER'S JOINT |

| A flat piece of corrugated slotted and scored is called a box blank. In order to make a box, the two ends must be joined in what is called the manufacturer's joint. For single and double wall cartons, these are most often joined with adhesive or tape. Almost all triple wall boxes are stitched. However, when extra strength is required, doublewall can also be stitched. |

|

|

Glued Joint |

|

Taped Joint |

|

Stitched Joint |

|

|

BOX DIMENSIONS |

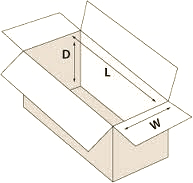

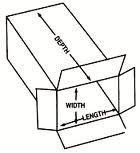

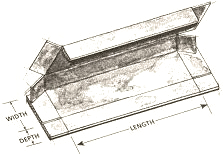

| Normally, the dimensions are given for the inside measurements (ID) in the order of Length(L) x Width(W) x Depth(D). Box dimensions are based on the rectangular opening of the box, the longer dimension being the length and the shorter the width. When measuring the depth of an end or top loading box, you must take into account the thickness of the four flaps which reduce the depth |

|

|

Top Loading |

|

End Loading |

| |

|

|

|

|

| Folders |

|

|